Raise Production Inc. has developed a flexible and staged approach to artificial lift for deviated and horizontal wellbores which are intended to work together to achieve ultimate hydrocarbon recovery.

The Solution

DIVIDE THE WELLBORE into Vertical and Horizontal flow scenarios that can be controlled. Vertical flow is well understood and the various flow regimes are controllable as the well ages and the flowing pressures decrease.

In contrast, horizontal flow from a reservoir is a relatively new concept to the industry. Raise has gained intrinsic empirical knowledge through numerous installations of multiple pumps along the horizontal wellbore. With this knowledge, Raise has developed the solutions necessary to overcome the complex horizontal flow challenges.

Through use of its proprietary technology, Raise provides both Evolutionary and Revolutionary “Life of the Well” Artificial Lift Solutions.

Beyond The Build

Controlled Flow Optimization

- Flow management to facilitate fuild separation

- Sand control prior to pump intake

- Address frictional concerns

Beyond The Build Is Adaptable For Use With

- Plunger Lift

- Electric Submersible Pumps

- Progressing Cavity Pumps

- Hydraulic Submersible Pumps

Artificial Lift

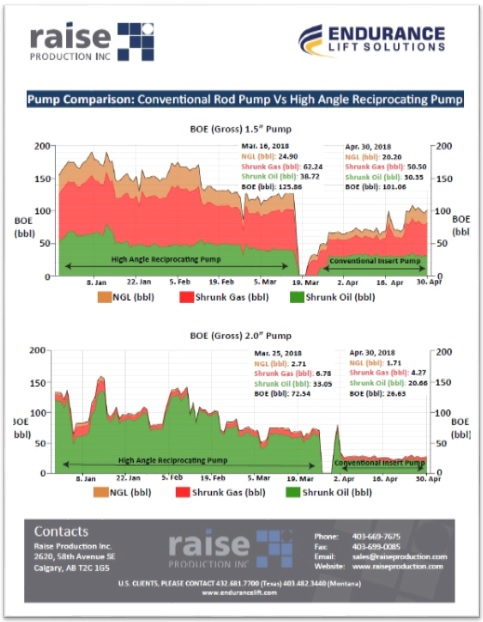

High Angle Reciprocating Pump (HARPTM)

- Eliminate gas-locking

- Increased efficiency with reduced rod and tubing wear

- Normally closed and guided valves

- Internal solids elimination

- Articulated features allow >15o deflection

- Can land below tangent or in wells with no tangent

- Better lift efficiency and slower stroke speed